What is the Americans with Disabilities Act?

The Americans with Disabilities Act of 1990 (ADA) prohibits discrimination and ensures equal opportunity for persons with disabilities in employment, State and local government services, public accommodations, commercial facilities, and transportation. Final regulations revising the Department’s ADA regulations, including its ADA Standards for Accessible Design was published in the Federal Register on September 15, 2010 (corrections to this text were published in the Federal Register on March 11, 2011). ADA covers all state and local governments, including those that receive no federal financial assistance.

While the ADA has five separate titles, Title II is the section specifically applicable to “public entities” (state and local governments) and the programs, services, and activities they deliver. The Department of Justice (“DOJ” or the “Department”), through its Civil Rights Division, is the key agency responsible for enforcing Title II and for coordinating other federal agencies’ enforcement activities under Title II. DOJ is the only federal entity with the authority to initiate ADA litigation against state and local governments for employment violations under Title I of the ADA and for all violations under Title II of the ADA.

Who does it Affect?

-

Americans with disabilities and their friends, families, and caregivers

-

Private employers with 15 or more employees

-

Businesses operating for the benefit of the public

-

All state and local government agencies

Title II of the Americans with Disabilities Act (ADA) requires that state and local governments ensure that persons with disabilities have access to the pedestrian routes in the public right of way. An important part of this requirement is the obligation whenever streets, roadways, or highways are altered to provide curb ramps where street level pedestrian walkways cross curbs. This requirement is intended to ensure the accessibility and usability of the pedestrian walkway for persons with disabilities.

What is the Difference between Maintenance or Alteration?

An alteration is a change that affects or could affect the usability of all or part of a building or facility. Alterations of streets, roads, or highways include activities such as reconstruction, rehabilitation, resurfacing, widening, and projects of similar scale and effect. Maintenance activities on streets, roads, or highways, such as filling potholes, are not alterations. Treatments that serve solely to seal and protect the road surface, improve friction, and control splash and spray are considered to be maintenance because they do not significantly affect the public’s access to or usability of the road. Some examples of the types of treatments that would normally be considered maintenance are: painting or striping lanes, crack filling and sealing, surface sealing, chip seals, slurry seals, fog seals, scrub sealing, joint crack seals, joint repairs, dowel bar retrofit, spot high-friction treatments, diamond grinding, and pavement patching. In some cases, the combination of several maintenance treatments occurring at or near the same time may qualify as an alteration and would trigger the obligation to provide curb ramps.

Where must Curb Ramps be Provided?

Generally, curb ramps are needed wherever a sidewalk or other pedestrian walkway crosses a curb. Curb ramps must be located to ensure a person with a mobility disability can travel from a sidewalk on one side of the street, over or through any curbs or traffic islands, to the sidewalk on the other side of the street. However, the ADA does not require installation of ramps or curb ramps in the absence of a pedestrian walkway with a prepared surface for pedestrian use. Nor are curb ramps required in the absence of a curb, elevation, or other barrier between the street and the walkway.

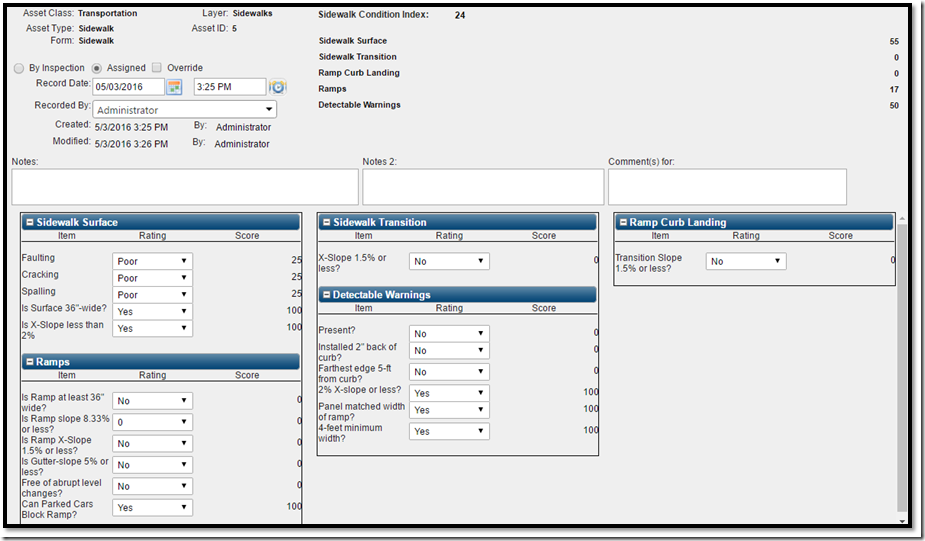

What are Detectable Warnings?

“A standardized surface feature built in or applied to walking surfaces or other elements to warn visually impaired people of hazards on a circulation path.“

- ADAAG: Required on curb ramps, hazardous vehicular areas, and reflecting pools, but not on doors to hazardous areas. The warnings must be truncated domes (§4.29).

- UFAS: “Tactile warnings” (uses different terminology) required only on doors to hazardous areas. Must be a textured surface on the door handle or hardware (§4.29).

As a Public Agency, How Should I approach Compliance with Limited Resources?

Public agencies are constantly chartered with conducting business and doing “more with less”. This includes achieving compliance with Federal Mandates that require infrastructure investment, but do not provide a funding mechanism to support it. In the industry, we call them “unfunded mandates”.

Many agencies struggle with these mandates for the following reasons:

- The existing infrastructure is non-compliant and therefore requires significant investment to bring it into compliance.

- Agencies do not have the ability to pay for the infrastructure enhancements required to achieve compliance.

- Agencies are hesitant to assess their compliance because if they document problems, then they feel obligated to fix them.

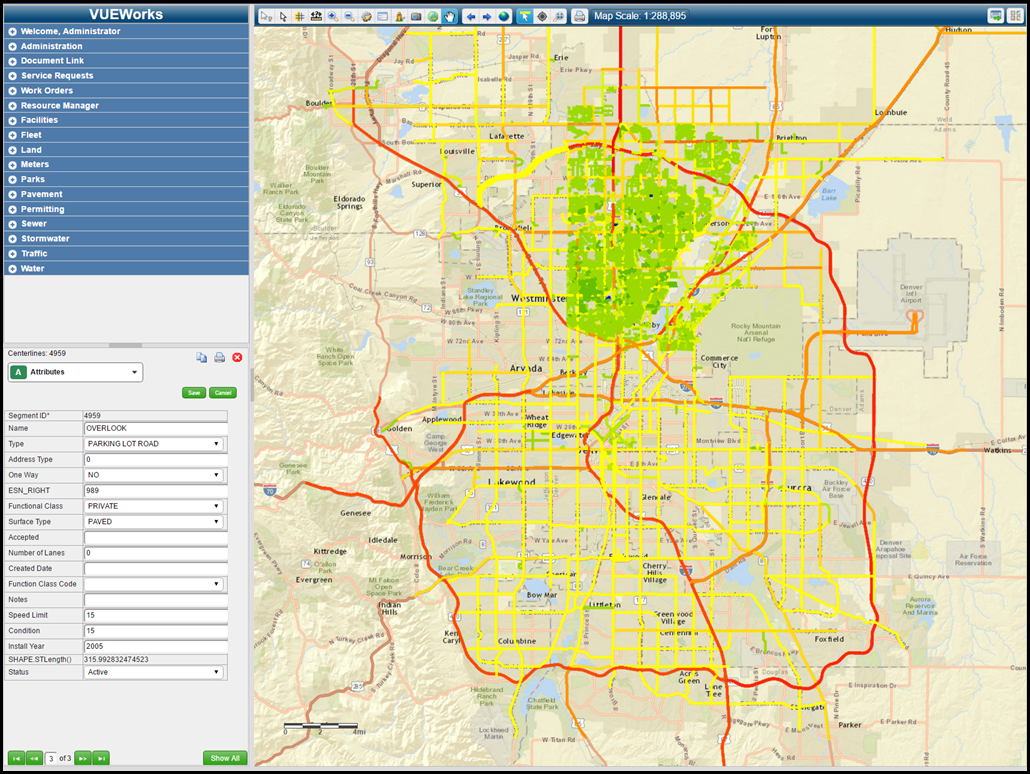

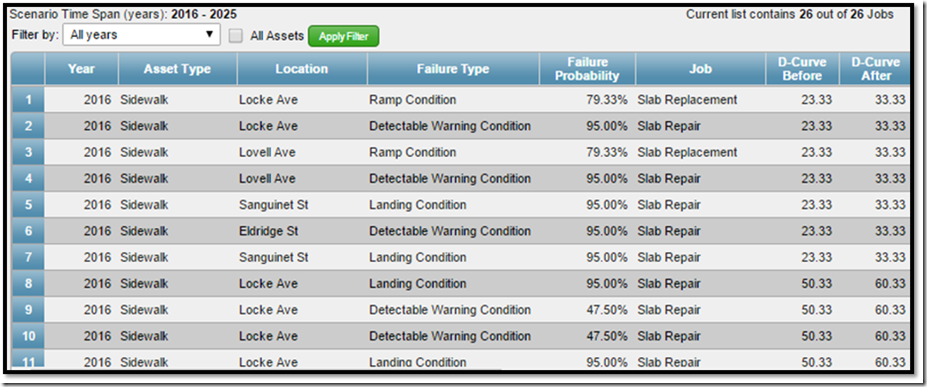

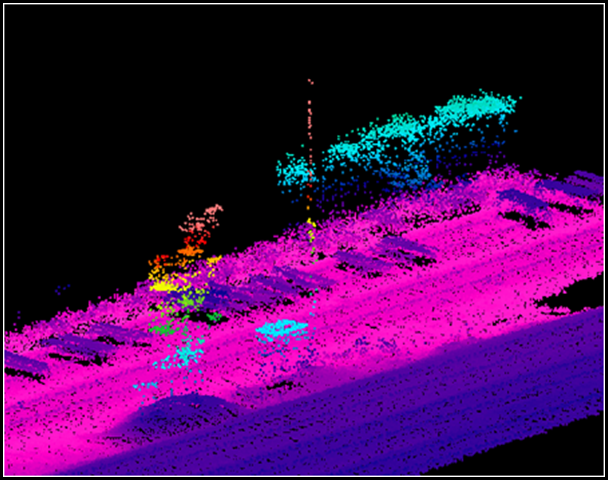

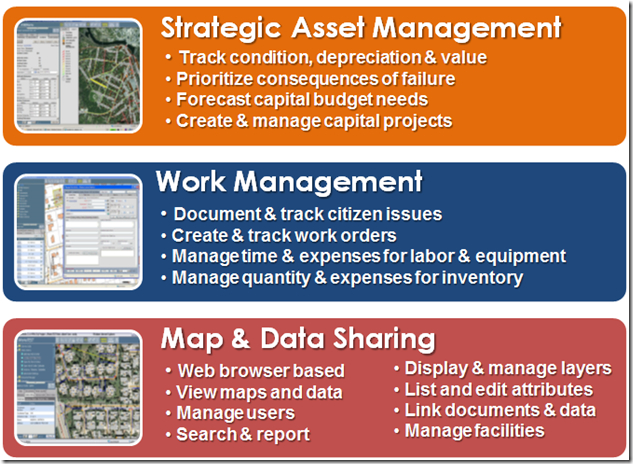

Therefore an attitude of “If I don’t know how bad the problem is, I can ignore it for the time-being…” becomes pervasive throughout many of these Public Entities. By “not knowing” how non-compliant their agency is in regards to this requirement, the agency is actually creating more litigation risk for itself. At VUEWorks, we have developed an ADA-compliance methodology that utilizes GIS and Risk-based prioritization to develop a long-term plan focused on ADA compliance.

The plan is simple and follows the typical Asset Management life-cycle approach:

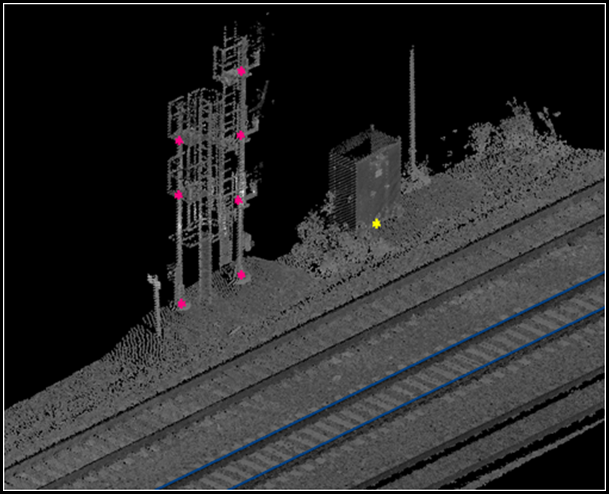

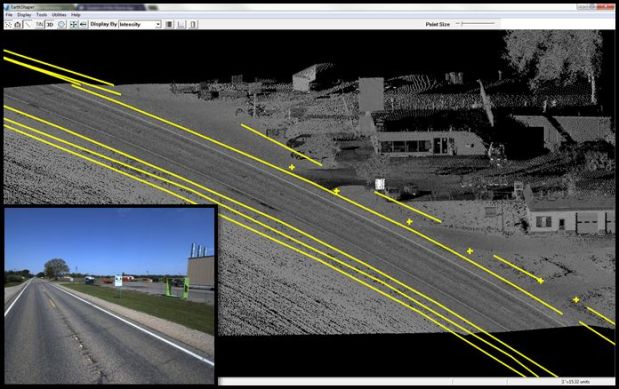

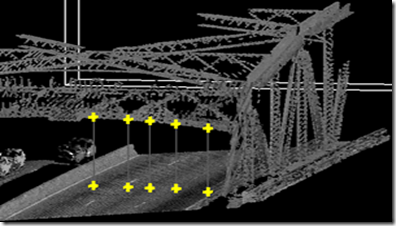

- Inventory – Utilizing GIS, mobile mapping and boots-on-the-ground inspection (where required).

- Assess – Visually inspect infrastructure assets and quantify their compliance.

- Prioritize – Develop a list of high-risk assets that need immediate attention.

- Execute – Re-construct, upgrade or maintain infrastructure assets that are part of an annual work plan.

- Rinse and Repeat – Execute work plan annually and re-assess the network of assets every 3-5 years to update the plan.

Next week’s blog will focus on how VUEWorks is utilized to achieve ADA compliance while limiting litigation risk to your agency…